Product: Lean Services

Company: Ricoh

My Role: Product Manager

Target Customer: Businesses with digital printing operations, such as a commercial printer or a large corporation with an internal printing operation.

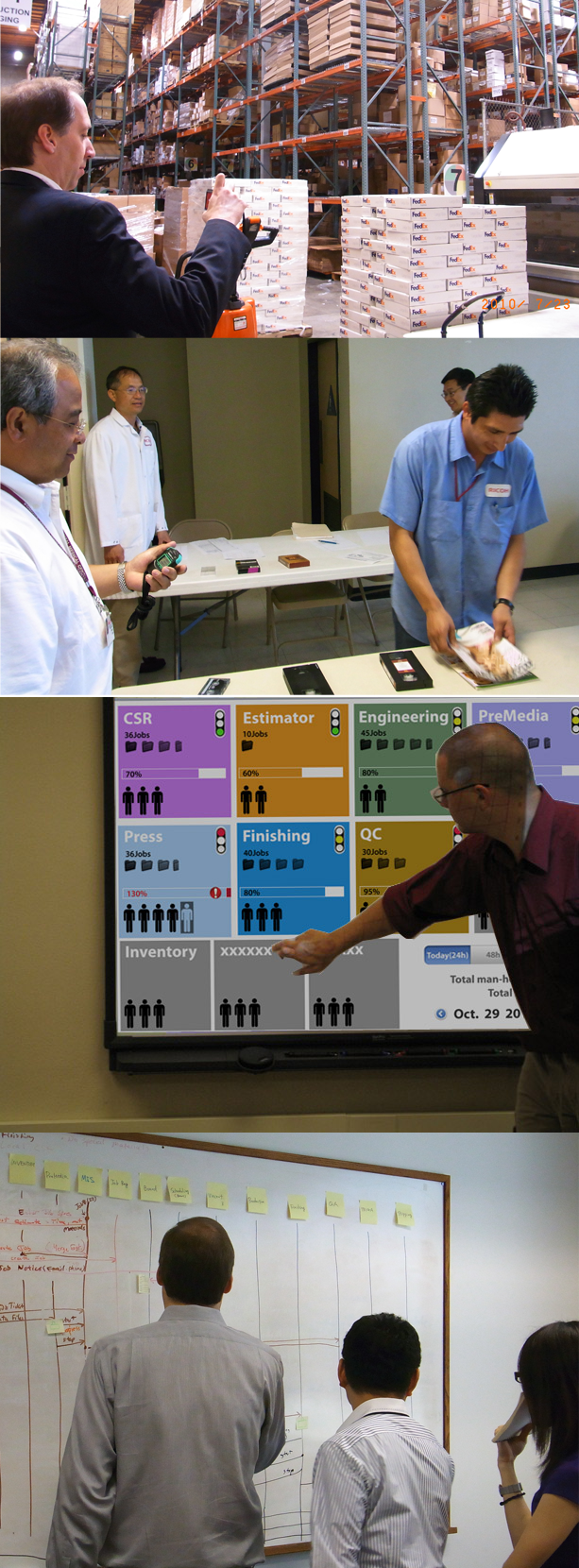

Overview: This was an interesting activity that consisted of two focus areas. A “lean service” transformational offering where Ricoh comes in and trains the customer on how to adopt Kaizen practices (AKA “Lean Production” or the “Toyota Method”). The second activity focused on understanding productivity issues in the customer environment that could be addressed with software solutions that Ricoh could develop. The underlying problem being addressed here is the introduction of new digital print technology that expands the business volume and increases the speed of work being completed. Lean services give employees digital tools to improve productivity, and empowers workers to adapt their processes and environment to the changing business.

Outcome: A “Kaizen Training” pilot was successful completed with a major commercial printer, it transformed the way they ran their operation and brought in new manufacturing technology that substantially improved their productivity by up to 34%. It validated the need and value of the service. In addition, extensive customer requirements were researched, documented, and validated in customer mockups, and were comprehended in future software offerings created by Ricoh.